Scroll

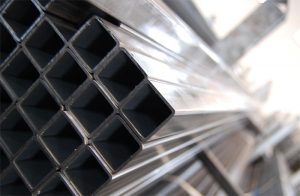

Present ever since the company’s foundation, this is its core department and includes raw, pickled, cold and hot galvanized pipes and tubular elements.

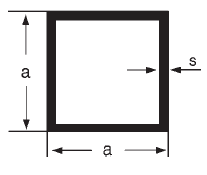

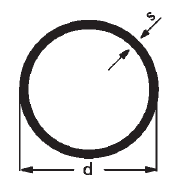

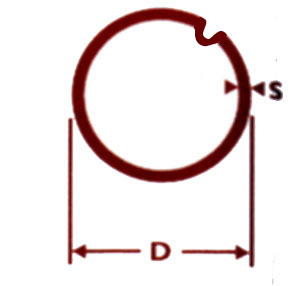

Available from stock, we provide the most comprehensive, highest quality and 100% Italian production range in the world. Production according to EN10219 for cold-rolled/hot-rolled steel products, raw, in grades S235JRH, S275JOH and S355J2H. Production according to EN10305-3 and EN10305-5 for cold-rolled/hot-rolled, pickled and Sendzimir galvanized steel products, in grades E220+CR2S2, up to high-strength E220+CR2S4; for cold-dip galvanized items, zinc coating is available from Z100 up to Z275. The material certification complies with EN10204 in 2.2 and 3.1 norms and are PDO and CE-marked. The wide range also includes hot-rolled galvanized pipes and tubular elements according to UNI ISO EN 1461:2009 and UNI EN ISO 14713:2010, part 1 and 2. These products are sold retail, by the bundle or in full loads with delivery of the material throughout Italy (including islands) and abroad (also for medium or small quantities). We can also cut to size upon request.

Steel tubes, profiles and tubulars

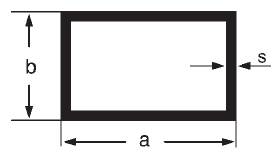

Iron pipes hold a prominent position in Fratubi’s product range. They come in round, square and rectangular shapes and can satisfy all customers’ requirements. They are used in light and heavy carpentry.

We also offer raw tubular elements for unfinished, iron fixtures. Pickled tubular elements can instead undergo treatments such as painting.

Sendzimir galvanized tubular elements for fixtures comply with UNI EN 10346 standards and have a higher corrosion resistance compared to other types. So, they can be used to skip a few steps in the production process and quickly complete the finished work.

Pipes and tubular elements made from pickled strips have a free of calamine surface and are suitable for painting. In certain cases, pipes made from cold-rolled strips can also be chrome-plated, but they are mostly useful for the production of material with small thicknesses > 1.5, which are mainly used in the furniture and decoration sector.

The products obtained by this process comply with UNI EN 10346, which has gradually replaced UNI EN 10327,UNI EN 10147and UNI EN 10292. Galvanising the surface does not completely eliminate the risk of oxidation. On the contrary, it can cause the formation of zinc carbonate cells, which appear as white, floury spots. In particular, this happens if the water with which the pipe metal sheet comes into contact with stagnates and does not run off. However, the treatment prevents the formation of rust, as it usually happens with raw steel. Material usually used for substructures.

Our range of products includes pipes and tubular elements for structural applications, hot formed in compliance with En 10210 and cold formed in compliance with En 10219 and following S275-S355 quality standards.

Hot formed structural pipes guarantee greater deformation possibilities, which is why they are used in areas subject to dynamic forces. Cold formed pipes, on the other hand, features a high mechanical strength and a high yield strength, which is why they are used for the construction of fixed load-bearing structures in civil, industrial and mechanical constructions.

Hot-rolled galvanized pipes feature a high resistance to rust formation and have a service life of between 20 and 50 years. They are widely used in carpentry in general and in many sectors, especially for products that are supposed to stay outdoors.

Marketing e Comunicazione

Marketing e Comunicazione